Maximize Safety with the Latest Confined Space Entry Equipment: A Comprehensive Guide

Working in confined spaces is essential for many industries, from construction and manufacturing to utilities and emergency services. These spaces can present unique challenges and pose significant risks to workers. As a result, it is crucial to understand the dangers associated with confined space entry and to use the appropriate equipment to maximize safety.

In this comprehensive guide, we will explore the risks associated with confined space entry, the importance of using the proper equipment, the different types of confined space entry equipment available, key features to consider when selecting equipment, and top brands in the industry. We will also discuss proper use and maintenance, training and certifications, OSHA regulations and guidelines, and answer frequently asked questions.

Understanding the risks and using the latest confined space entry equipment can significantly reduce the likelihood of accidents and injuries in these challenging environments.

Understanding the risks of confined space entry

Confined spaces are defined as areas not designed for continuous occupancy with limited access and egress. Examples include tanks, silos, tunnels, and pipelines. These spaces can pose a variety of hazards to workers, including:

- Atmospheric hazards: Confined spaces may contain dangerous levels of gases, vapors, or dust, leading to asphyxiation, explosions, or fires. Oxygen levels can also be dangerously low or high, causing suffocation or other health issues.

- Engulfment hazards: Loose materials, such as sand or grain, can engulf and trap workers, causing suffocation or crushing injuries.

- Physical hazards: Confined spaces often have limited visibility, making it difficult to see potential hazards such as exposed wiring, sharp objects, or unstable structures.

- Biological hazards: Sewers and other spaces may contain bacteria, viruses, or other harmful organisms that can cause illness or infection.

- Psychological hazards: Working in confined spaces can cause stress, anxiety, and claustrophobia, impacting workers’ mental health and well-being.

Given these risks, using the appropriate confined space entry equipment is crucial to protect workers’ health and safety.

The importance of confined space entry equipment

Using the right confined space entry equipment is essential for ensuring the safety of workers entering and working in these hazardous environments. This equipment serves several purposes, including:

- Monitoring and controlling atmospheric conditions: Gas detectors and ventilation equipment help ensure that the air inside the confined space is safe to breathe and free from dangerous contaminants.

- Preventing engulfment: Barriers, shields, and other devices can help prevent workers from becoming engulfed by loose materials.

- Ensuring safe access and egress: Ladders, tripods, and winches provide secure and stable means for workers to enter and exit confined spaces.

- Protecting against physical hazards: Personal protective equipment (PPE), such as hard hats, gloves, and safety glasses, help protect workers from injuries caused by physical hazards.

- Enhancing communication and visibility: Radios, lighting, and other communication devices allow workers to maintain contact with those outside the confined space and improve visibility.

Investing in the right confined space entry equipment can minimize the risks associated with working in these environments, helping to prevent accidents and save lives.

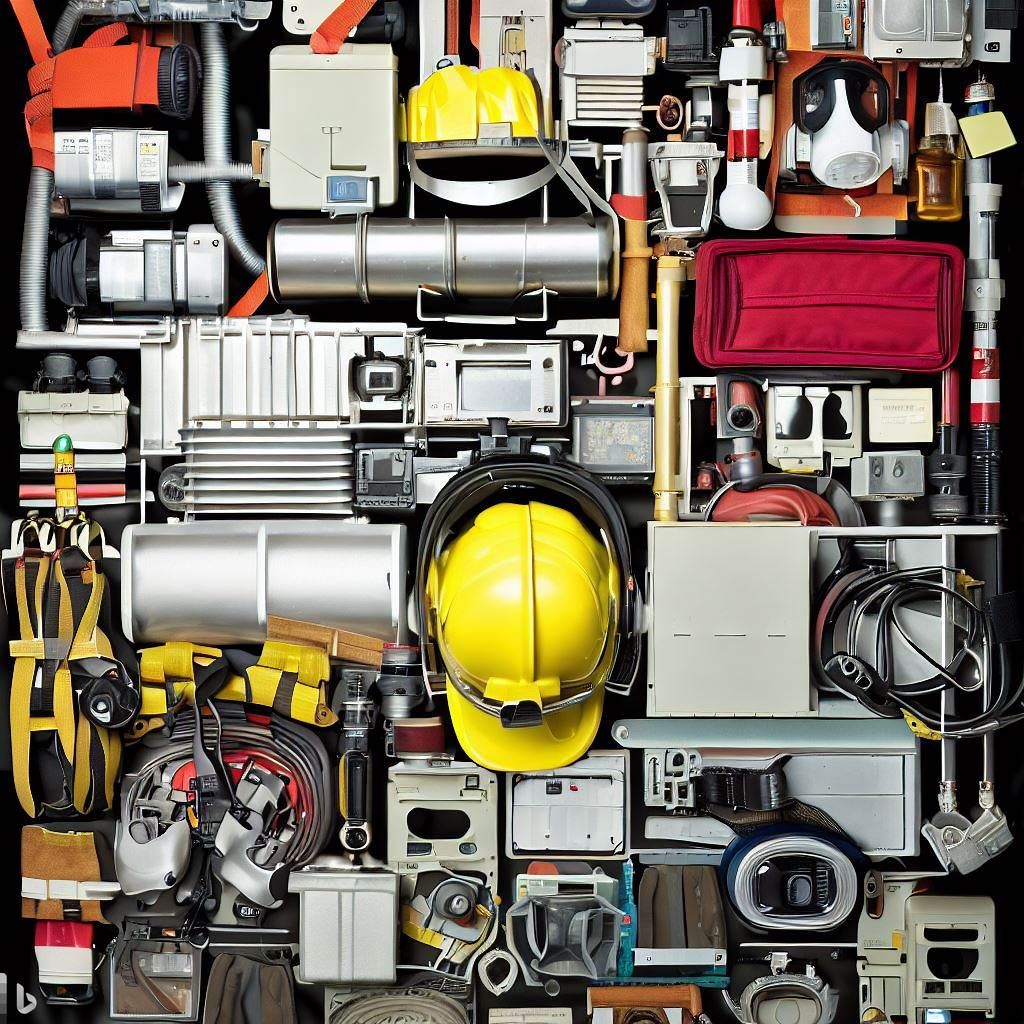

Types of confined space entry equipment

A wide range of confined space entry equipment is available to address the various hazards and challenges associated with working in these environments. Some examples of equipment include:

Gas detection and monitoring equipment

Gas detectors and monitors are essential for identifying and measuring dangerous gases and vapors in confined spaces. These devices can be fixed or portable and detect various gases, such as carbon monoxide, hydrogen sulfide, and methane.

Ventilation equipment

Proper ventilation is crucial for maintaining safe atmospheric conditions within a confined space. Ventilation equipment, such as blowers, fans, and ducts, helps to ensure a continuous supply of fresh air and remove harmful contaminants.

Access and retrieval systems

These systems provide safe and secure means for workers to enter and exit confined spaces. They can include tripods, davit arms, winches, hoists, ladders, and other access equipment.

Personal protective equipment (PPE)

PPE is essential for protecting workers from physical hazards associated with confined space entry. This can include hard hats, safety glasses, gloves, respiratory protection, and protective clothing.

Communication and lighting devices

Effective communication and adequate lighting are essential for worker safety in confined spaces. Radios, headsets, and other communication devices allow constant contact between workers and those outside the space. Lighting equipment, such as headlamps and portable work lights, provides necessary illumination for safe work.

Key features to consider when selecting confined space entry equipment

When choosing confined space entry equipment, several factors must be considered to ensure you select the right tools for your specific needs. These include:

- Compatibility: Ensure that the equipment you choose is compatible with the specific confined space you will be working in and with other equipment you may be using.

- Durability: Look for equipment made from high-quality materials that can withstand the harsh conditions often found in confined spaces.

- Ease of use: Select equipment that is easy to operate and maintain, minimizing potential errors and reducing the risk of accidents.

- Portability: Choose equipment that is easy to transport and set up, especially if you work in multiple locations or need to move equipment between sites frequently.

- Compliance: Ensure that the equipment you select meets or exceeds relevant regulatory requirements and industry standards, such as those set by OSHA, ANSI, or other organizations.

By considering these factors, you can select the best-confined space entry equipment for your needs, helping to maximize safety and minimize risks.

Top confined space entry equipment brands

Many manufacturers and brands of confined space entry equipment offer various products and solutions to meet your needs. Some top brands in the industry include:

- MSA Safety: MSA is a leading provider of safety products, including gas detection and monitoring equipment, respiratory protection, and fall protection systems.

- Honeywell: Honeywell offers a variety of confined space entry equipment, such as gas detectors, ventilation equipment, and PPE.

- 3M: 3M is well-known for its extensive range of PPE, including respirators, hearing protection, and protective clothing.

- Allegro Industries: Allegro specializes in confined space ventilation equipment, blowers, and accessories.

- Capital Safety: Capital Safety, a part of 3M, offers fall protection equipment, such as harnesses, lanyards, and self-retracting lifelines, designed specifically for confined space applications.

By selecting equipment from reputable brands, you can trust that you are investing in quality products that will help ensure worker safety in confined spaces.

Proper use and maintenance of confined space entry equipment

To maximize the effectiveness and longevity of your confined space entry equipment, it is essential to use and maintain it correctly. Some tips for proper use and maintenance include:

- Follow manufacturer instructions: Always read and follow the manufacturer’s guidelines for using and maintaining your equipment, as this will ensure that it operates effectively and safely.

- Inspect equipment regularly: Before each use, inspect your equipment for signs of wear, damage, or malfunction. Regularly scheduled maintenance checks should also be performed as recommended by the manufacturer.

- Keep equipment clean: Clean it regularly to remove dirt, debris, and contaminants that could impact its performance.

- Store equipment properly: Store your confined space entry equipment in a clean, dry, and secure location when not in use, protecting it from damage and extending its lifespan.

- Replace damaged or expired equipment: If your equipment is damaged, malfunctioning, or past its expiration date, replace it immediately to ensure worker safety.

By properly using and maintaining your confined space entry equipment, you can help to ensure its effectiveness and extend its lifespan, providing the best possible protection for workers in these hazardous environments.

Training and certifications for confined space entry

Workers must receive proper training and certifications to work safely in confined spaces. Training programs should cover hazard recognition, safe work practices, confined space entry equipment use, and emergency response procedures. Some key certifications and training programs include:

- OSHA 29 CFR 1910.146 Permit-Required Confined Spaces: This standard requires employers to train employees who work in permit-required confined spaces, ensuring they have the knowledge and skills necessary to perform their duties safely.

- Confined Space Entry and Rescue Certification: This certification, offered by organizations such as the National Fire Protection Association (NFPA) or the Occupational Safety and Health Administration (OSHA), teaches workers how to safely enter, work in, and rescue individuals from confined spaces.

- Manufacturer-specific training: Many equipment manufacturers offer training programs on the proper use and maintenance of their products, helping workers to use the equipment safely and effectively.

By obtaining the appropriate training and certifications, workers can be well-prepared to handle the challenges and hazards of confined space entry.

OSHA regulations and guidelines for confined space entry equipment

OSHA has established regulations and guidelines for confined space entry to protect workers from the hazards associated with these environments. Some key regulations and guidelines related to confined space entry equipment include:

- OSHA 29 CFR 1910.146 Permit-Required Confined Spaces: This standard outlines the requirements for employers to protect workers from confined space hazards, including appropriate equipment and training.

- OSHA 29 CFR 1910.134 Respiratory Protection: This regulation establishes the requirements for respiratory protection in confined spaces, including the proper selection, use, and maintenance of respirators.

- ANSI/ASSP Z117.1 Safety Requirements for Confined Spaces: This consensus standard provides guidance on the selection and use of confined space entry equipment, including gas detection, ventilation, and access equipment.

By adhering to these regulations and guidelines, you can help ensure that your confined space entry equipment complies and provides the necessary protection for workers.

Conclusion and next steps for maximizing safety in confined spaces

Confined space entry presents unique challenges and hazards that require specialized equipment to ensure worker safety. By understanding the risks associated with these environments, selecting the appropriate confined space entry equipment, and ensuring proper use and maintenance, you can significantly reduce the likelihood of accidents and injuries.

As you move forward, consider the following next steps:

- Assess your confined space entry equipment to ensure it meets industry standards and is in good working condition.

- Research and invest in the latest confined space entry equipment technologies to enhance worker safety and efficiency.

- Ensure workers receive the appropriate training and certifications to work safely in confined spaces and operate the required equipment effectively.

By taking these steps, you can help to create a safer work environment for those who must enter and work in confined spaces, ultimately protecting lives and reducing the risk of accidents and injuries.

Frequently Asked Questions:

Q: What is the difference between a permit-required and a non-permit-required confined space?

A: A permit-required confined space is a space that has one or more of the following characteristics: contains or has the potential to contain a hazardous atmosphere, contains material with the potential for engulfment, has an internal configuration that could trap or asphyxiate an entrant, or contains any other recognized serious safety or health hazard. A non-permit-required confined space does not have any of these hazards.

Q: How often should confined space entry equipment be inspected?

A: Confined space entry equipment should be inspected before each use and regularly scheduled maintenance checks should be performed as the manufacturer recommends. Additionally, equipment should be inspected after any incident or event that could have caused damage or compromised its integrity.

Q: What should be included in a confined space entry safety plan?

A: A confined space entry safety plan should include hazard identification and assessment, procedures for safe entry and work, appropriate confined space entry equipment, communication protocols, emergency response procedures, and training and certification requirements for workers.