Mastering Confined Space Tripod Requirements: A Comprehensive Guide for Safety Professionals

As a safety professional, it is essential to be well-versed in the various aspects of confined space safety, including properly using confined space tripods. These essential equipment play a critical role in ensuring the safety of workers who must enter and perform tasks in confined spaces. This comprehensive guide will give you the knowledge you need to master confined space tripod requirements and help create a safer work environment for all.

This article will cover the following topics: understanding confined spaces and their hazards, the importance of confined space tripods in safety operations, key components of a confined space tripod system, and meeting OSHA and ANSI confined space tripod requirements.

Selecting the right confined space tripod for your workplace, proper setup and use of confined space tripods, inspection, maintenance, and storage of confined space tripods, confined space tripod training and certification, and finally, additional resources for safety professionals. By the end of this guide, you will have a thorough understanding of confined space tripod requirements and be better equipped to ensure the safety of your workers in confined space environments.

Understanding confined spaces and their hazards

A confined space is an area not intended for continuous human occupancy and has limited means of entry and exit. These spaces can be found in various industries and settings, including tanks, silos, pits, tunnels, pipelines, and more. Confined spaces pose significant risks to workers due to their potential for hazardous atmospheres, engulfment, entrapment, or other dangers.

Hazards in confined spaces can include a lack of oxygen, the presence of toxic or flammable gases, liquids or solids that can engulf a worker, and physical hazards such as moving parts or electrical hazards. Safety professionals need to be aware of these hazards and implement proper safety measures, including using confined space tripods, to reduce the risks associated with working in confined spaces.

Importance of confined space tripods in safety operations

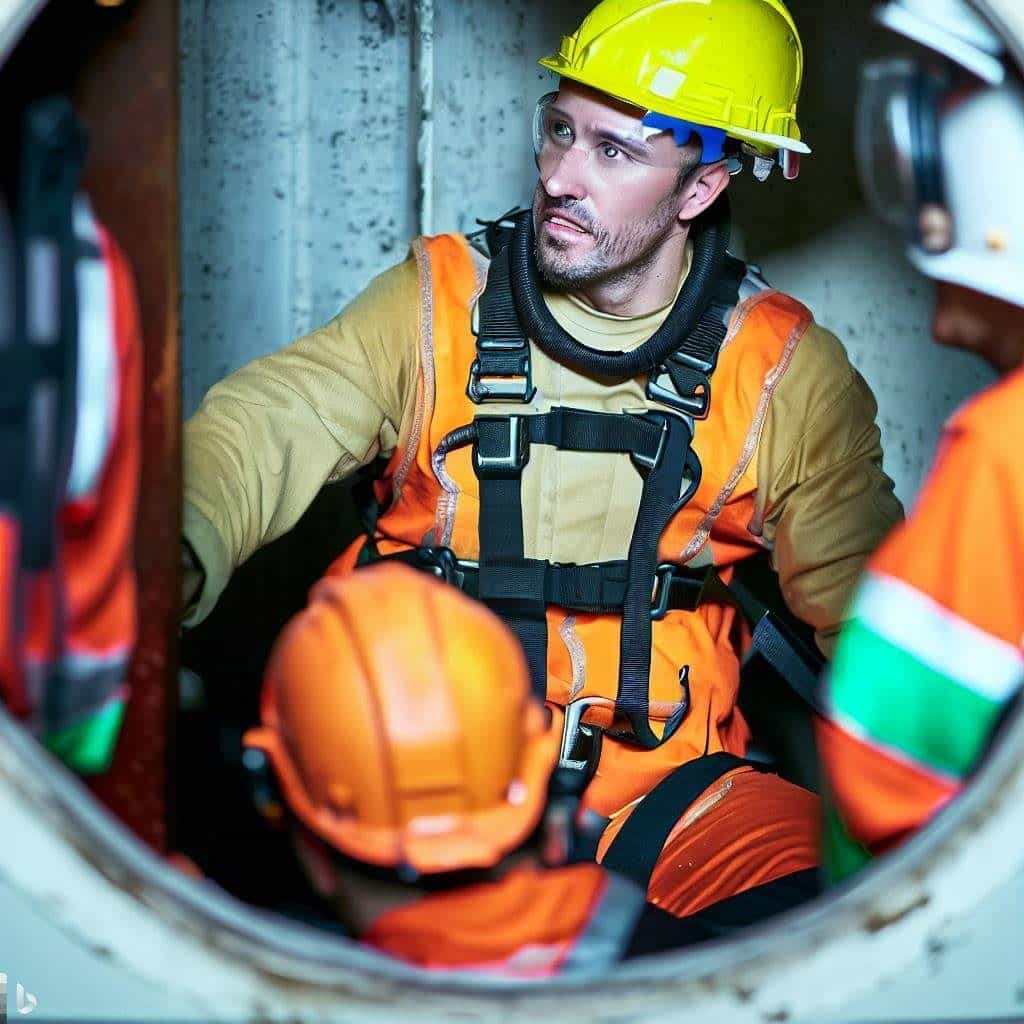

Confined space tripods are crucial in ensuring the safety of workers entering, working in, and exiting confined spaces. These devices serve as an anchor point for personal fall protection systems, such as body harnesses and self-retracting lifelines, and provide a means for workers to be safely lowered into and raised out of confined spaces. They can also be used to facilitate rescue operations in the event of an emergency.

A confined space tripod can significantly reduce the risk of injury or fatality associated with falls, entrapment, or engulfment. Additionally, tripods can help prevent unauthorized entry into confined spaces, as they can be set up to block access points and deter individuals who have not received proper training or authorization from entering these hazardous areas.

Key components of a confined space tripod system

A confined space tripod system typically consists of several key components, including the tripod itself, a winch or hoist, a body harness, and a self-retracting lifeline. Each of these components plays a critical role in ensuring the safety and effectiveness of the system.

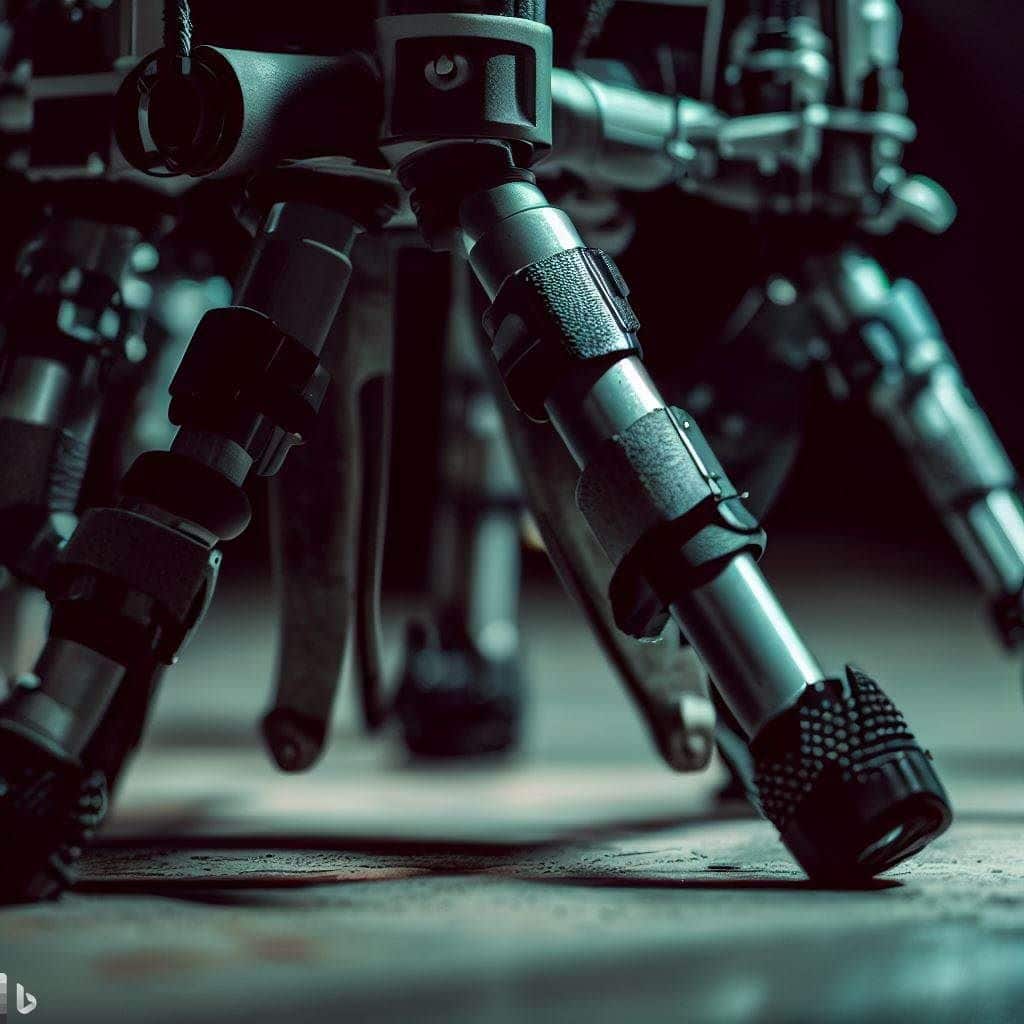

Tripod

The tripod is the primary support structure and anchor point for the confined space entry and rescue system. It should be constructed from durable materials like aluminum or steel to ensure stability and longevity. The tripod’s legs should be adjustable to accommodate various heights and terrain, and its feet should be equipped with non-slip pads or spiked shoes for secure placement on various surfaces.

Winch or hoist

A winch or hoist is used to raise safely and lower workers into and out of the confined space. It should have a mechanical advantage system to facilitate easy and controlled movement and a braking mechanism to prevent accidental free falls. The winch or hoist should also be compatible with the tripod and designed for confined space entry and rescue operations.

Body harness

A full-body harness is worn by the worker entering the confined space and connects to the self-retracting lifeline or other fall arrest equipment. The harness should be comfortable, adjustable, and designed for confined space entry and rescue operations. It should also be equipped with a dorsal D-ring for attachment to the lifeline or other fall arrest equipment and additional attachment points for rescue operations.

Self-retracting lifeline

The self-retracting lifeline connects the worker’s body harness to the tripod and provides fall protection by automatically arresting a fall should one occur. The lifeline should be constructed from durable materials, such as stainless steel or galvanized steel cable, and equipped with a locking mechanism to prevent accidental disengagement.

Meeting OSHA and ANSI confined space tripod requirements

As a safety professional, it is crucial to ensure that your confined space tripod system meets the requirements set forth by the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI). These organizations have established specific standards for confined space entry and rescue equipment, including tripods, to ensure the safety of workers.

OSHA’s confined space standard (29 CFR 1910.146) outlines the requirements for safe entry and work in confined spaces, including proper fall protection and rescue equipment. While this standard does not provide specific requirements for confined space tripods, it does mandate that equipment used for confined space entry and rescue be designed and manufactured to meet applicable ANSI standards.

ANSI standard Z359.18-2017, “Safety Requirements for Anchorage Connectors for Active Fall Protection Systems,” provides detailed specifications for confined space tripods and other anchorage connectors used in fall protection systems. This standard outlines requirements for materials, design, strength, and testing of confined space tripods to ensure their safety and effectiveness in protecting workers from falls.

As a safety professional, you are responsible for ensuring that your confined space tripod system meets these OSHA and ANSI requirements to provide your workers with the highest level of safety.

Selecting the right confined space tripod for your workplace

Choosing the appropriately confined space tripod for your workplace is essential in ensuring the safety of workers entering and working in confined spaces. Several factors should be considered when selecting a tripod, including the following:

- Size and height: The tripod should be adjustable to accommodate various confined space entry points and provide sufficient height for workers to be safely lowered into and raised out of the space.

- Weight capacity: The tripod should have sufficient weight capacity to support the worker’s combined weight, personal protective equipment, and any tools or materials they may carry.

- Material: The tripod should be constructed from durable materials, such as aluminum or steel, to ensure its stability and longevity.

- Compatibility with other equipment: The tripod should be compatible with the winch or hoist, body harness, and self-retracting lifeline used in the confined space entry and rescue system.

- Compliance with OSHA and ANSI standards: The tripod should meet the requirements set forth by OSHA and ANSI to ensure its safety and effectiveness in protecting workers from falls.

By carefully considering these factors, you can select the ideal confined space tripod for your specific workplace needs and ensure the safety of your workers.

Proper setup and use of confined space tripods

To ensure the safety and effectiveness of your confined space tripod system, it is crucial to follow proper setup and usage procedures. The following steps outline the general process for setting up and using a confined space tripod:

- Inspect the tripod and equipment: Before each use, inspect the tripod and all associated equipment for any damage, wear, or corrosion that could compromise its safety or effectiveness.

- Assemble the tripod: Set up the tripod according to the manufacturer’s instructions, ensuring the legs are properly adjusted and secured and the feet are positioned securely on the ground.

- Attach the winch or hoist: Secure the winch or hoist to the tripod’s head assembly according to the manufacturer’s instructions, ensuring it is properly aligned and locked in place.

- Connect the self-retracting lifeline: Attach the lifeline to the winch or hoist and the worker’s body harness, ensuring the connection points are secure and the lifeline is free from obstructions.

- Enter the confined space: With the confined space tripod system and the worker properly secured, they may be safely lowered into the confined space using the winch or hoist.

- Monitor the worker: While in the confined space, continuously monitor their safety and communicate with them regularly to ensure their well-being.

- Exit the confined space: When the worker is ready to exit the confined space, use the winch or hoist to raise them out of the area safely.

By following these steps and adhering to the manufacturer’s instructions for your specific tripod system, you can help ensure the safety of your workers. At the same time, they perform tasks in confined spaces.

Inspection, maintenance, and storage of confined space tripods

Regular inspection, maintenance, and storage of your confined space tripod system are essential to ensure its continued safety and effectiveness. The following guidelines can help you maintain your tripod and associated equipment in optimal condition:

- Inspect equipment before each use: Before using your confined space tripod system, carefully inspect the tripod, winch, hoist, body harness, and self-retracting lifeline for any signs of damage, wear, or corrosion that could compromise their safety or effectiveness.

- Perform periodic inspections: In addition to pre-use inspections, perform periodic inspections of your tripod system according to the manufacturer’s recommendations and OSHA and ANSI requirements. These inspections should be more thorough and may include disassembling and examining individual components for signs of wear or damage.

- Clean and maintain equipment: Keep your confined space tripod system clean and well-maintained by following the manufacturer’s recommendations for cleaning and lubricating various components. Proper maintenance can help extend the lifespan of your equipment and ensure its continued safety and effectiveness.

- Store equipment properly: When not in use, store your confined space tripod and associated equipment in a clean, dry, and secure location to prevent damage from moisture, dust, or other contaminants. Avoid storing equipment in direct sunlight, as UV radiation can cause the degradation of certain materials over time.

By following these guidelines and adhering to the manufacturer’s recommendations for your specific tripod system, you can help ensure the longevity and reliability of your confined space entry and rescue equipment.

Confined space tripod training and certification

Proper training and certification are crucial for ensuring workers’ safety using confined space tripods and associated equipment. OSHA requires employers to provide training for all employees who work in or around confined spaces, including those who use tripods and other entry and rescue equipment.

Training should cover the proper use, inspection, maintenance, and storage of confined space tripods, the hazards associated with confined spaces, and the necessary precautions for working in these environments. Additionally, workers should receive training in confined space rescue procedures and using other fall protection and rescue equipment, such as body harnesses and self-retracting lifelines.

Third-party organizations or equipment manufacturers typically provide certification for confined space entry and rescue training. Select a reputable training provider that adheres to OSHA and ANSI requirements to ensure your workers receive the highest quality training and certification.

Conclusion and additional resources for safety professionals

Mastering confined space tripod requirements is essential to ensuring the safety of workers who must enter and perform tasks in confined spaces. By understanding the hazards associated with confined spaces, selecting the appropriate tripod system, and following proper setup, use, inspection, maintenance, and storage procedures, you can help create a safer work environment for all.

Many resources are available to safety professionals seeking to further their knowledge of confined space safety and tripod requirements. OSHA’s website offers a wealth of information on confined space regulations and best practices, as well as numerous publications and training materials. Additionally, the ANSI website provides access to their standards and guidelines for confined space tripods and other fall protection equipment.

By continually expanding your knowledge and staying up-to-date on the latest regulations and best practices, you can ensure the safety of your workers and maintain a culture of safety in your workplace.

Frequently Asked Questions:

What is a confined space tripod?

A confined space tripod is a piece of safety equipment used to support and anchor fall protection systems for workers entering and working in confined spaces. These tripods provide a means for workers to be safely lowered into and raised out of confined spaces and serve as anchor points for fall arrest and rescue systems.

Why are confined space tripods necessary?

Confined space tripods are necessary to ensure the safety of workers who must enter and perform tasks in confined spaces. These devices provide critical support and anchorage for personal fall protection systems, such as body harnesses and self-retracting lifelines. They can facilitate rescue operations in the event of an emergency.

What are the key components of a confined space tripod system?

A confined space tripod system typically consists of several key components, including the tripod itself, a winch or hoist, a body harness, and a self-retracting lifeline. Each of these components plays a critical role in ensuring the safety and effectiveness of the system.

What are the OSHA and ANSI requirements for confined space tripods?

OSHA’s confined space standard (29 CFR 1910.146) outlines the requirements for safe entry and work in confined spaces, including proper fall protection and rescue equipment. ANSI standard Z359.18-2017 provides detailed specifications for confined space tripods and other anchorage connectors used in fall protection systems, including materials, design, strength, and testing requirements.

What should I consider when selecting a confined space tripod for my workplace?

When selecting a confined space tripod for your workplace, consider factors such as size and height, weight capacity, material, compatibility with other equipment, and compliance with OSHA and ANSI standards. By carefully considering these factors, you can select the ideal tripod for your specific workplace needs and ensure the safety of your workers.